Jeld Wen & Masterwood. Do it soon ... do it well!!!

by Roberto Muccini, Masterwood Communication Manager

A few days ago we held, at our Rimini factory, a FAT (Factory Acceptance Test) for an important doors production plant.

There were representatives of Jeld Wen, the customer company, and Nicholaisen who followed the contract on Masterwood SpA's behalf.

Jeld Wen è un gruppo internazionale specializzato nella produzione di porte e finestre, tra i primi al mondo per fatturato.

JELD-WEN was founded in 1960 when American entrepreneur Richard Wendt bought an Oregon millwork plant with 15 employees. Today the company spans across 22 countries in North America, Europe and Australia,it has approximately 150 divisions employing more than 20,000 people.

Jeld Wen's inspiration is founded on high end craftsmanship and technology.

So it is an honor for Masterwood to have been chosen as CNC supplier by such a company.

This is why we had a brief interview with Kim Jobling, Jeld Wen Scandinavia Senior Production Developer and Thomas Biehl – director of Nicholaisen A/S.

Q:

Dear Kim, we are happy you have chosen Masterwood for your CNC needs. Please could you explain what drove you to 'ask for more'? What were Jeld Wen goals?

Kim: Jeld Wen was looking for a more updated production system that could be used for "individual" doors but also for "consumer market". We needed something that could apply for both.

In other words we had a "quantity per shift" goal to be fulfilled and a "quality" goal at the same time.

We (Jeld Wen, Nicholaisen AS and Masterwood) did a great job to setup a customized production line that meets all our specifications.

Q:

Dear Thomas, when you met Jeld Wen representatives, why did you consider of Masterwood as the CNC supplier?

Thomas: We were looking for someone with the right competence about doors production, in particular large scale production.

We were also looking for a partner who had internally the capability to 'challenge normal thinking'.

We made a survey on the market of CNC woodworking companies and Masterwood convinced us they would be the ideal partner.

We started up our cooperation together in a long and profitable work, made up of data exchange, brainstorming meetings, etc.

This work led us here, checking on the field the machines performance and we must say that Masterwood fulfilled the specifications on a level which is above than expected.

We therefore look forward to further collaborations in the future.

Thomas and Kim, thank you again for you kindness. We also look forward to working together again!

Here follows a brief summary of the line performance.

Data Summary

The line "in pills"

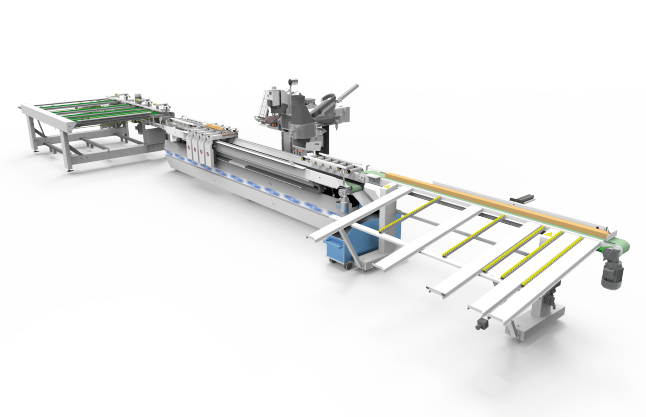

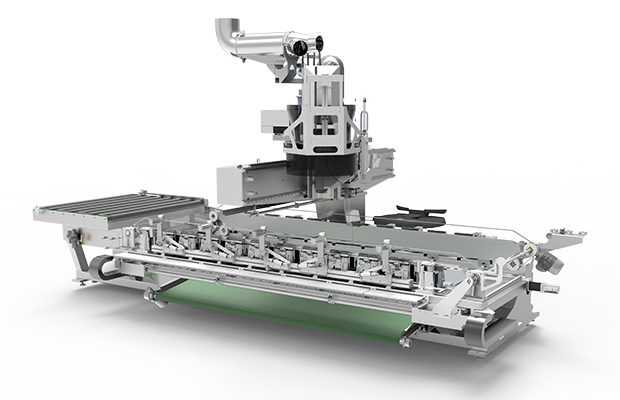

This complete line, designed in strong cooperation with the customer, owns top level characteristics regarding production rate, factory automation, 24h/24h monitoring.

| Production Rate | Up to 2 doors/min and more. |

|---|---|

| Door Length | 600 mm (min) / 2900 mm (max) |

| Door Width | 250 mm (min) / 1500 mm (max) |

| Door Thickness | 30 mm (min) / 90 mm (max) |

| Door weight | Up to 150 kg |