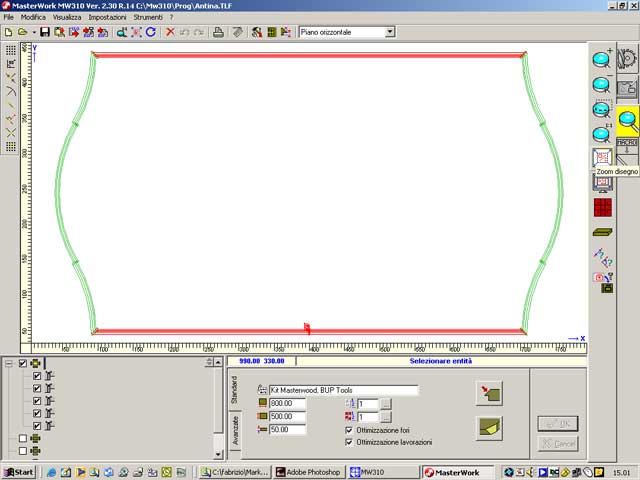

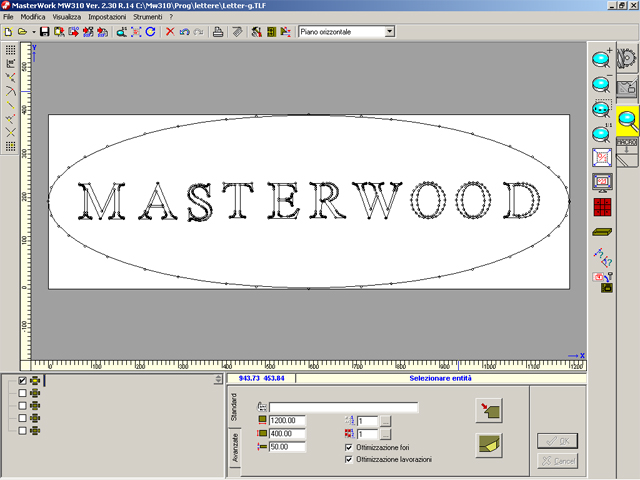

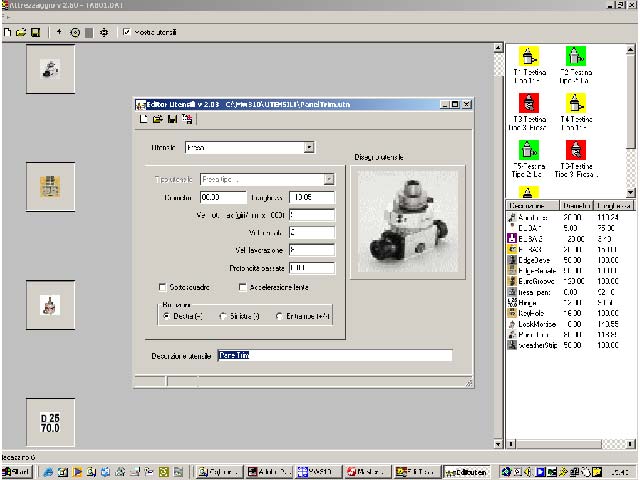

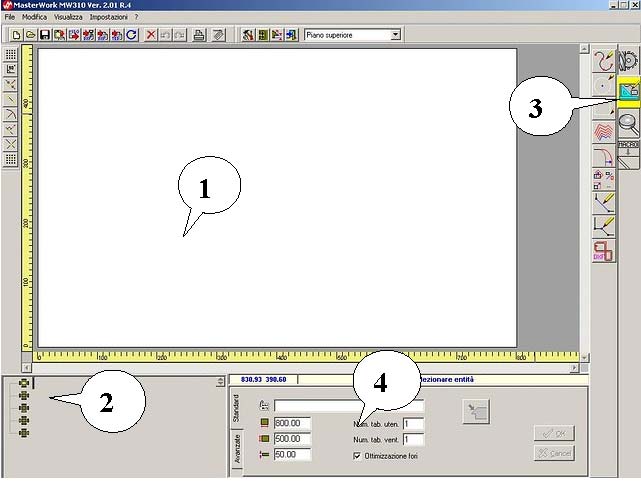

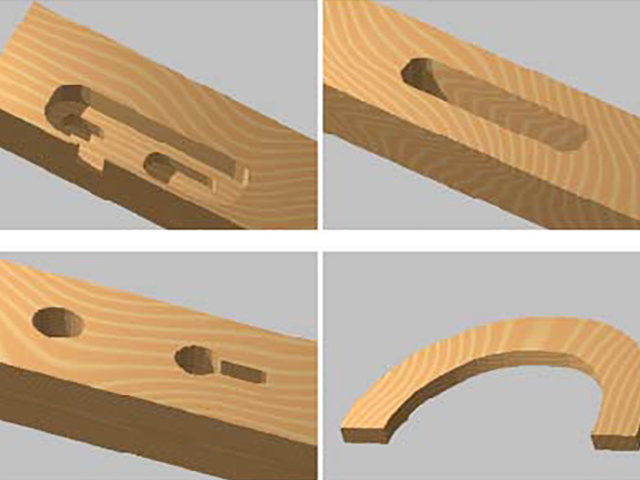

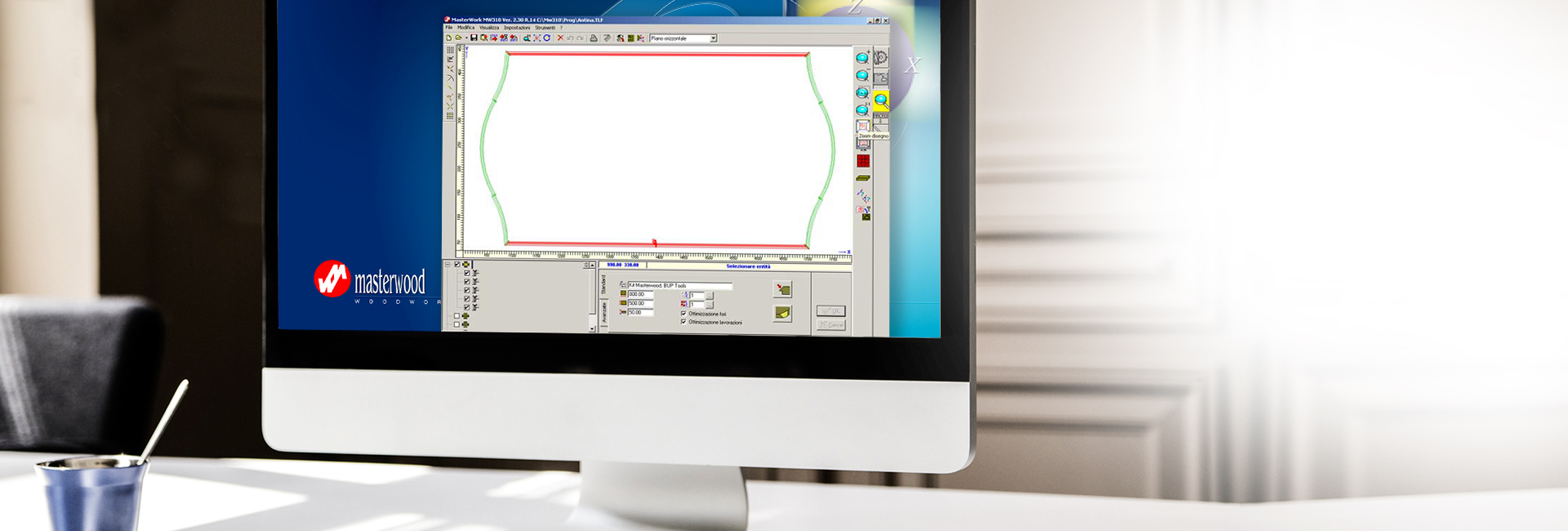

Masterwork is a graphic programming system which allows to avoid the Iso programming thanks to an easy, fast and intuitive graphic interface. This because Masterwork is not a graphic compiler of lines (ISO), but it's a real programming environment oriented to the work piece. It is a tool for all users, but specially dedicated to whom have no experience of programming.

The MasterWork office version that Masterwood deliver it standard with all the machines, allows the customer to generate the programs in the office and load them via internet or duongle key in the machine.

Masterwork complies with windows standards and guarantees the immediate and easy understanding of all commands.

Masterwork Software: Woodworking CNC

MASTERWORK: Skillness in the factory!

Masterwork

Skillness in the factory!

Structured on several levels, it is a suitable tool not only for advanced users, but it can also be easily used by people with no programming experience on CNC machining centers.

The MasterWork office version that Masterwood deliver it standard with all the machines, allows the customer to generate the programs in the office and load them via internet or duongle key in the machine..

Info request

The Masterwood staff is happy to support you for any information about this product!