Grabex Windows

Leading UK windows manufacturer purchases Masterwood CNC 4WIN

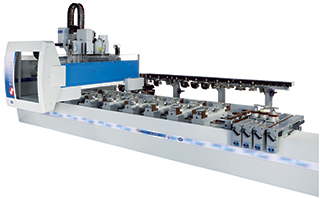

In the first half of 2013 Masterwood installed the first UK based 4WIN CNC machine for the production of windows and doors at south London company Grabex Windows.

With a factory based in North Surrey, and two showrooms, the company offers a complete service supplying and fitting windows, doors, and conservatories in timber, Upvc, and aluminium. The

company launched new profiles for their products at various exhibitions they participated in which provided a lot of new enquiries which prompted managing director, Michael Grabowski, to look at a more efficient production system for his timber department.

With CNC machines already in use in the Upvc and aluminium workshops it was decided to follow the same route for timber. After extensive research into the various options for window production Michael and a colleague visited the Masterwood showroom and factory in Rimini to see various demonstration of the 4WIN CNC, which met all

their requirements.

Once an order was placed Grabex worked with Masterwood and Whitehill Tooling to get the correct tooling stacks to produce their range of windows, doors, and sliding sashes.

The machine consists of a four axis 11kw liquid cooled router, 50 tooling positions, a patented fully automatic bed and clamping system, along with four standard CNC bed supports for shaped

work.

Several weeks of installation by Masterwood technicians had the new tooling working with the machine through the MasterWindow software which allows any shape of window to be designed in minutes, cutting sheets produced with glass sizes, and machining programmes generated for every component. The machine’s operating system, Master AT, is then used to optimise the components on to the bed, which automatically positions the support arms and clamps once the programmes are selected. The timber is put in place and all operations are carried out, including jointing, inner and outer profiling, bead retrieval, and all ironmongery workings.

Once the staff at Grabex had got used to the new system the manufacturing time for timber windows was reduced and allowed more output to be achieved. Already the company has seen a

reduction in total manufacturing times and a big reduction in timber wastage.

The 4WIN CNC can produce around 50 windows (frame and two sashes) per week, or in the region of 750 components, depending on sections and work required.

We look forward to working further with Grabex Windows as their business expands and they kindly allow other potential customers to visit their works to see the 4WIN in action.