Technical specifications

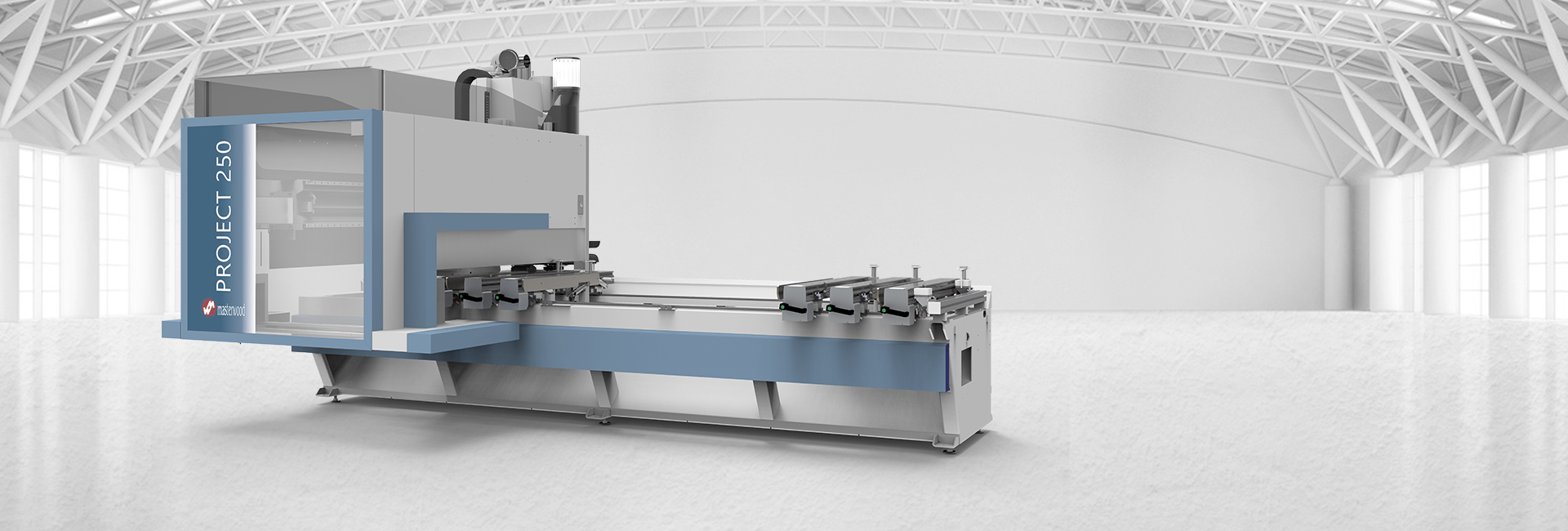

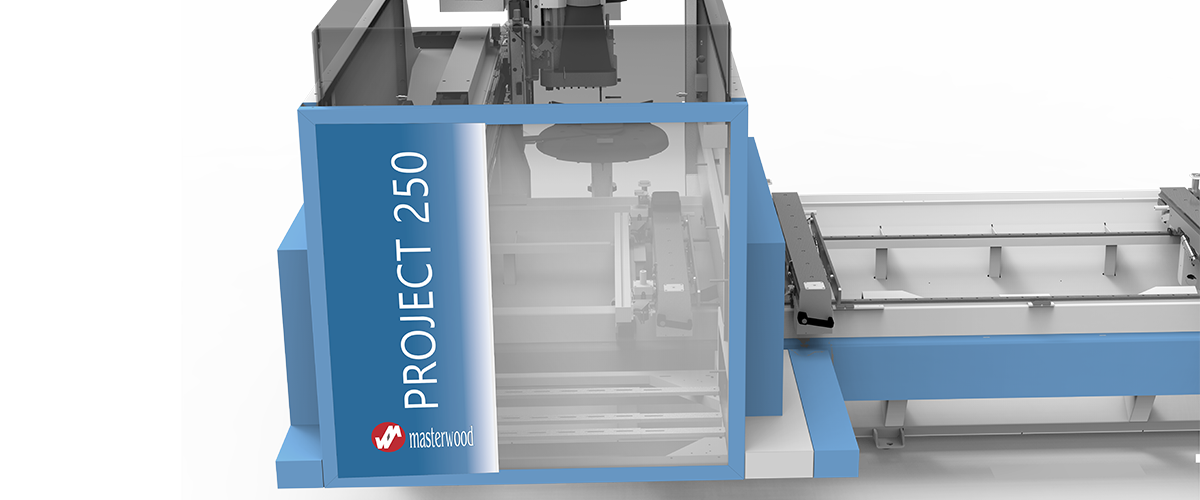

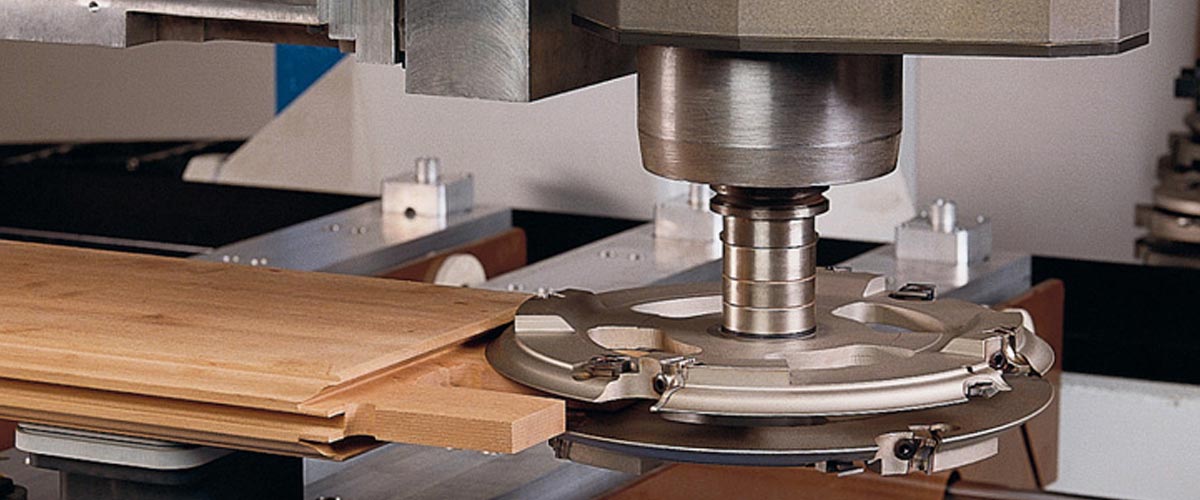

Project 250 is the machining center for drilling wood panels, particularly suitable for the production of doors and windows.

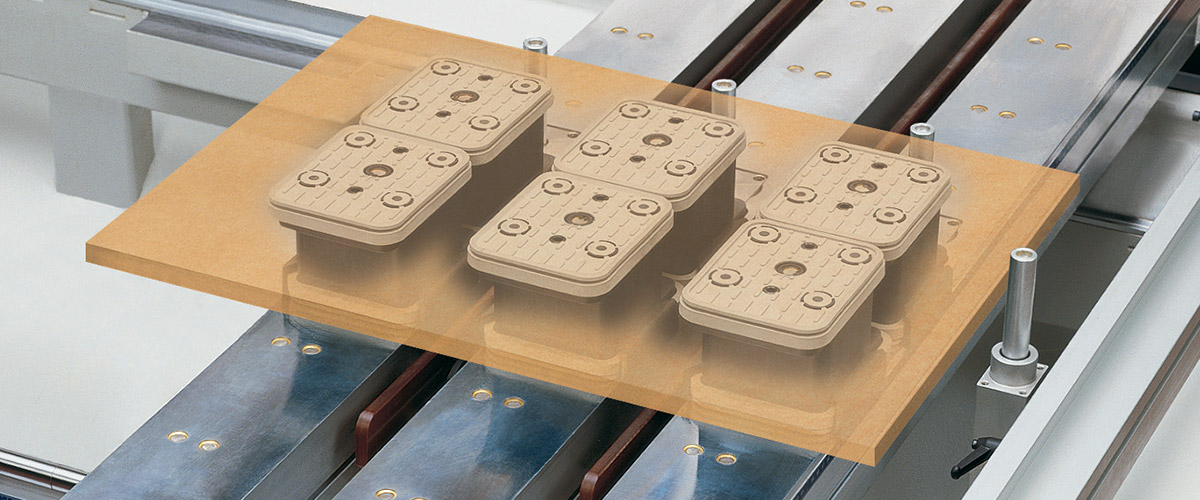

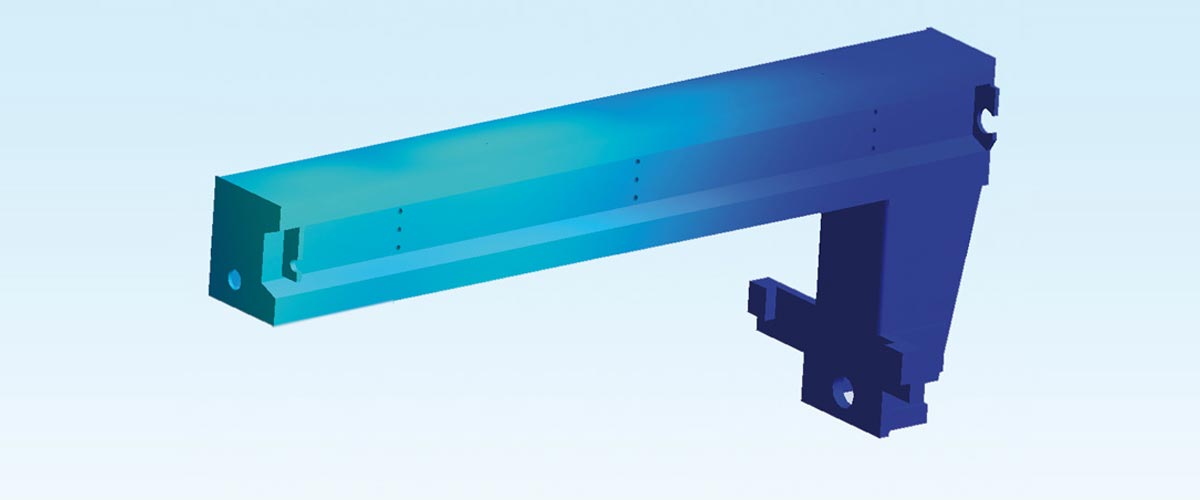

It's possible to machine panels without width limits, the 13 kW electrospindle with HSK - F63 connection quickly make it the ideal machine for machining wooden panels and derivatives, as well as doors.It's perfect for small factories but lends with excellent results also in the medium and big company, for the execution of "out of standard" and prototypes.