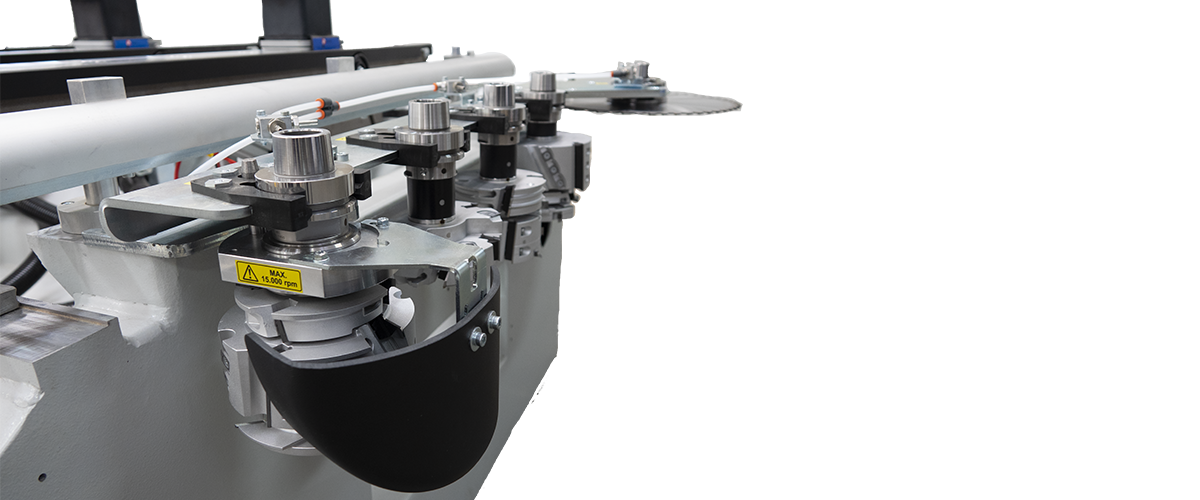

Project 485 is the 5-axis machining center for advanced furniture manufacturers.

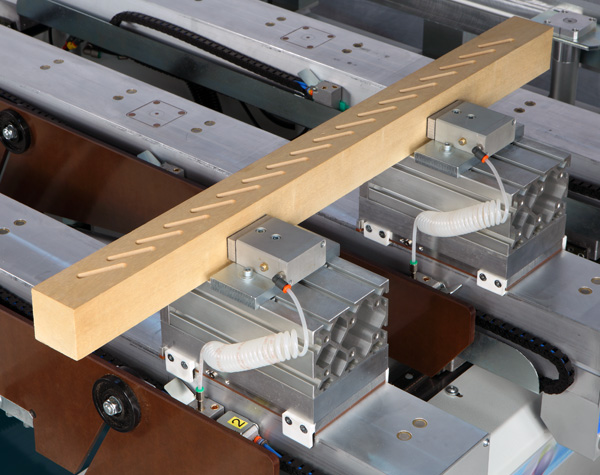

The "cantilever" structure allows loading of rather wide panels. The use of birotative operatin unite gives Project 485 a great flexibility without the need to use expensive aggregates, as for example in the case of cuts on inclined planes.