High Production and Flexibility: The Dream of any modern company!

Masterwood and ITA install a plant for doors production at Classen-Pol factory in Rybnik.

Loosely based on article by Alicja Bagnucka of Kurier Drzewny800.000 interior doors per year are produced in this plant at Classen-Pol factory in Rybnik. A truly impressive number that lets you get the idea of the challenge awaiting Masterwood.The

Customer Requests

"Our request was clear. Production process improvements, in terms of quality and number of defects" - says Marek Pakula, The Head of the doors production department at Classen-Pol.

"The major advantages of this system, designed and built by Masterwood, are the speed of the machines and the absence of the need to move items from a machine to another. Everything is done in the production line."

"Whenever a worker takes the material in his hands, regardless of whether it is a door or something else, it's a waste of time, energy and, more important, a possible source of errors."

"The automated system is never wrong! All the faults may happen on the line, are automatically reported. The stop of the entire process takes place only if the quality parameters do not match, or if an error in the program bar code reader occurs."

The Masterwood Solution

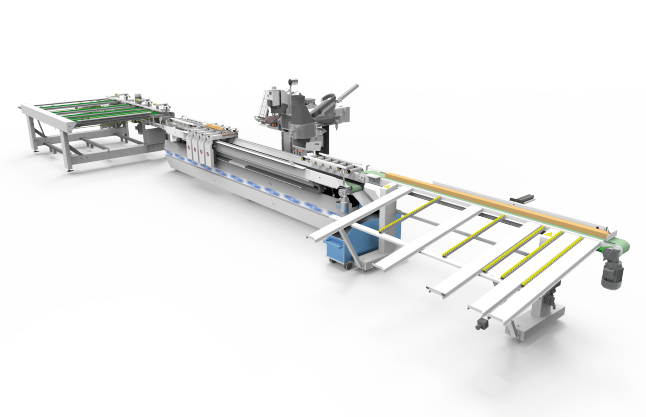

"The production line is tailor-made designed on the customer specifications, placed organically into the existing production system" - says Andrzej Głuchowski - president of the company ITA, the plant supplier and distributor of Masterwood machines in Poland.

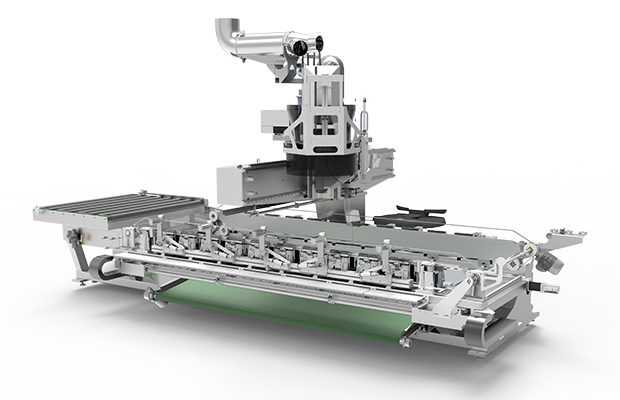

"The door goes first in a machine for locks and hinges milling. Following there are two Project Doors arranged in parallel and the line manager software automatically sends the door to the first available machine. It's a dynamic process. At last there is the stacking of finished products. "

"With such a volume of production, Classen-Pol cannot afford the minimum downtime. As a result, the line must ensure a continuous operation either in case of mass production or batch-one size. Furthermore, this line can product different doors in parallel on two machines. That gives you the maximum flexibility in terms of small batches ant it was impossible with the old production line. The programming activity is done by a single person. Everything is prepared in advance, and the operator chooses from a list of selected programs and receives the pallets with the machined products.”

On-line remote service

The machines are connected in real time with the headquarters in Italy and Masterwood, following a request of an oprator or a technician, is able to check the real operating conditions of production line. The Italian engineers have everything under control and are able to intervene remotely in a fast and effective way.

On-site service is always ready!

“The "on site" technical support service is managed by ITA, carried out by skilled technician. These technicians are periodically trained in the Masterwood headquarters in Rimini- Italy. So we can face any problem and find a solution.” - says Sandro Lancerotto, Area Manager for Poland of Masterwood company.

The Masterwood know-how is available to all manufacturers of doors! Contact Us!