Info request

The Masterwood staff is happy to support you for any information about this product!

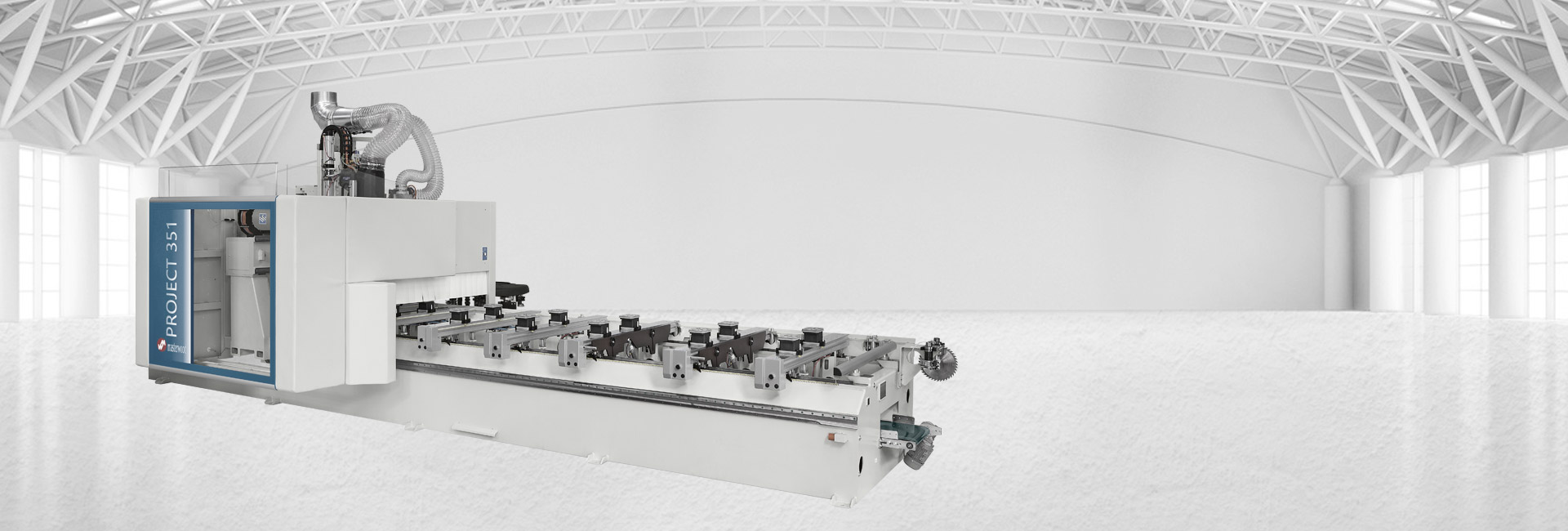

| Description | Project 351 | project 351L | UM |

|---|---|---|---|

| Working Area X-Y-Z | 3220-1550-200 | 5170-1550-200 | mm |

| Boring head - total spindles | 19 | 19 | |

| Electrospindle - max power | 12 - HSK 63F | 12 - HSK 63F | kW |

| Saw blade - maximum diameter | 125 | 125 | |

| Tools magazine - max n. of tools |

22 (std) + 4 (opt) | 22 (std) + 4 (opt) | |

| Max tool diameter | 250 (280 sawblade-opt) |

250 (280 sawblade-opt) |

mm |

| Max. vacuum pump | 100 (std) + 100 (opt) | 100 (std) + 100 (opt) | m3/h |